Total Seal: Total Conform Piston Rings

Conforming to Pressure

Saving weight has always been a mantra in motorsports. Every ounce counts and racers will spend a lot of time (and money) gutting interiors or replacing fenders and bumpers with aluminum or space-age carbon fiber materials. Shaving a few pounds has also lead to aluminum heads and blocks, titanium hardware and lighter weight materials in the engine as well.

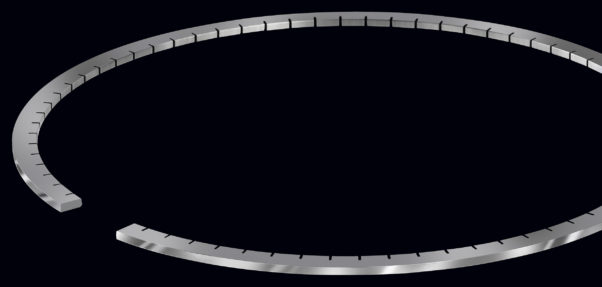

The radiused slots in the inside of the Total Conform Ring provide the ability to retain a seal against the cylinder wall during times of cylinder distortion.

With aluminum engine blocks, iron sleeves (which are sometimes rather thin) are pressed into the block to guide the piston through its travel and to contain the insane cylinder pressures created during the combustion process. With the combustion events occurring hundreds of times a second, not to mention heat cycles of the block itself, the form of the cylinder can actually distort.

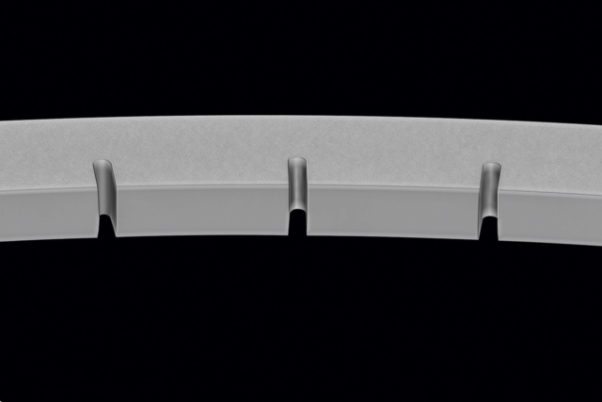

Notice the radius form of the ring slots. The smooth radius is needed to prevent stress points and helps the ring conform to cylinder deviations then return to its original form.

When cylinder distortion occurs, it can cause leakage points between the piston rings and the cylinder wall. Piston rings are designed to seal a round cylinder, or a slightly egg shaped cylinder at best. Any disruptions to the cylinder form will cause pressure leakage around the rings which will adversely affect the compression and the resulting power stroke. In short, a loss of performance.

But what if a piston ring could be made to follow the form of these cylinder distortions to seal the pressure into the area above the piston? That’s what the engineering team at Total Seal asked themselves with the result being their Total Conform Piston Rings.

Every ring goes through a number of quality tests during the manufacturing process including a back-light test. This step ensures there is a complete seal with no voids where pressure could escape.

The Total Conform Ring, which are used only in the top ring position, has a series of radial notches around its inner diameter. This design reduces stress risers as well as the chance of the ring fracturing while maximizing the ring’s ability to conform to the cylinder creating an effective seal.

Fitment checks are made during the CNC process as well. Here the ring fitment is being confirmed in one of the precise cylinder gauges.

The form shifting abilities of the Conform Rings was designed to seal in combustion pressures, but their design also resulted in a lighter and more flexible ring. These added characteristics lead to less friction, reduced oil consumption and can even help with gas loading which keeps the ring sealed against the cylinder wall, much like a gas ported ring.

The Total Conform Rings, which are a patented design, are used by professional Pro Stock, Cup cars and other high level race teams, but they’ve also found a home with restricted sportsman racing classes where a piston ring must measure to stock specifications. The Total Conforms are available in stock dimensions but their design results in a lighter ring with more flexibility, improved sealing and less friction which can add up to big performance benefits in highly restricted race engines.

Total Seal offers the Total Conform rings in a number of sizes and materials, depending on the application and use of the engine. The metal used is based on the amount of heat the ring will be experiencing as well as the length of time. Due to these variances, it’s best to call one of Total Seal’s tech experts to discuss the engine build and racing to ensure the best ring possible for the build.